Categories

FAQ

-

Are SAL products compatible with third party controls such as cbus?

Are SAL products compatible with third party controls such as cbus?

Unless specified in writing and in consideration of the ongoing upgrade in technology and operating standards, SAL is unable to confirm performance compatibility with third party control devices. It is the responsibility of the installer to confirm performance compatibility, (inclusive of control and function limits) before installation.

-

Are there is restrictions to the type of insulating material covering an IC-4 rated product?

Are there is restrictions to the type of insulating material covering an IC-4 / IC-F rated product?

YES, AS/NZS6058 test procedures stipulate the type of insulated material composition covering an IC-4 / IC-F rated product being equivalent to formed insulation, where 200mm is equivalent to an R1 4.0 classification in accordance with AS/NZ4859.1.

-

Can I cover my LED panel with thermal insulation?

Can I cover my LED panel with thermal insulation?

Unless the product is provided with a designated IC rating, (which would typically be located on the product rating label); the answer is NO.

This instruction would also apply to any associated LED driver supplied with the panel.

-

Can I mount a Stargem SE7080 product under a covered eave?

Can I mount a Stargem SE7080 product under a covered eave?

Allowing for the impact (if any) and suitable drainage of water, the product has been designed and approved for installation in an exposed, vertical wall mount orientation only.

Mounting the product in a horizontal orientation voids the designated IP rating of the product, hence installation in such an orientation must not be exposed to any water ingress whatsoever.

-

Cutting LED Strip kits

My LED strip KIT, which I have just cut to (a shorter) length, is momentarily "blinking" or "flickering" when I turn the LED OFF.

This event is not a safety issue and typically occurs when the LED Strip load falls below the threshold of the driver design limit, which will result in a minor capacitive discharge in the form of the LED strip momentarily "blinking" or "flickering" when the power is turned off. When cutting LED strips KITS, it is always important to calculate the remaining LED load to reconfirm its compatibility with the existing driver, as driver changes may be required with moderate reduction in loads,

-

Dimming products what are the issues?

Dimming products what are the issues?

As there is no global performance standard for dimming devices (other than safety and EMC) it is important to consulate with your supplier the compatibility of the devices you propose to install. Minimum loads and dimming performance limits are critical ratings that must be considered when using such devices.

-

Does SAL have office locations nationally?

Does SAL have office locations nationally?

Yes, Hamer NZ. P# 0800 239 239

-

Does SAL offer extended warranties?

Does SAL offer extended warranties?

Yes and these warranty extensions are detailed on the relevant product installation sheet or web page.

-

Facebook – Does SAL have a facebook page?

Facebook – Does SAL have a facebook page?

Yes, www.facebook.com/salnational

-

I have a warranty claim who do I contact?

I have a warranty claim who do I contact?

This first point of contact should be the place of original purchase, after which they will be responsible to coordinate the warranty communication with the SAL’s local Customer service team.

-

If I remove or change a factory fitted plug and or lead is my warranty void?

If I remove or replace a factory fitted plug and or lead is my warranty void?

The replacement or removal of a factory fitted plug or lead does not void a products warranty, conditional the task has been completed by a qualified installer in accordance with all relevant Australian and New Zealand standards.

-

Instagram Does SAL have an Instagram feed?

Instagram Does SAL have an Instagram feed?

Yes @salnational

-

Is aiming orientation important for exterior products?

Is aiming orientation important for exterior products?

Absolutely, careful attention is required when installing exterior products to ensure the designated aiming orientation is correct and allows for the natural cleaning of debris/dust from the glass visor surface, in particular when aimed in an upward direction. Products aimed in an upward direction can result in a build-up of dirt on the glass visor, which in turn can thermally stress the product if it is not routinely cleaned. Any aiming restrictions can be found with the installation instructions located in the product carton and or on the relevant product web page.

-

Is it mandatory for in-scope products and (or carton packing where the product size is too small) to be marked with the RCM logo?

Is it mandatory for in-scope products and (or carton packing where the product size is too small) to be marked with the RCM logo?

Yes.

-

Is lumen maintenance and rated life the same?

Is lumen maintenance and rated life the same?

Simple answer is NO. Although documented as “hours” Lumen maintenance with LED products is calculated through the combination of LM79, LM80 and TM21 reporting methodologies and reflects as a guide “useful” time duration of the light source. Rated life on the other-hand (when stated) denotes the rated average LED failures over a given time, shown typically shown as rated survival hours. Now don't get this subject confused with PRODUCT WARRANTY, for SAL product warranty offer, check out the warranty statement found here and on the product installation sheet.

-

Is SAL National Australian owned and operated?

Is SAL National Australian owned and operated?

Yes, since 1998

-

Is Sunny Lighting the same as SAL National?

Is Sunny Lighting the same as SAL National?

Yes (Sunny Australia Lighting) is SAL National Pty Ltd

-

LED what does it stand for?

LED what does it stand for?

Light Emitting Diode, with the first (red) visible spectrum LED being invented in 1962 by Nick Holonyak

-

Product maintenance is it important?

Product maintenance is it important?

The simple answer is Yes. Electrical products are just like your vehicle when it comes to maintenance requirements. They both collect dust and require cleaning and they both have components that require routine inspection and adjustments. Please refer to any specific maintenance instruction on the SAL installation sheet or web site.

-

RCM mark what does it mean?

RCM mark what does it mean?

This mark, which is mandatory for in-scope lighting and electrical products in Australia and New Zealand, which confirms the product complies with applicable safety and EMC standards.

-

SDOC what does it mean?

SDOC what does it mean?

Suppliers Declaration of Conformity. A SDOC is typically a document that a supplier generates to confirm mandatory safety and performance testing for a particular product has been completed, in lieu of distributing expansive original test reports, which generally are best read by qualified persons. At a minimum a SDOC for lighting equipment should present the relevant Safety and EMC test reports and test report numbers, together with the relevant model numbers of the equipment being offered. The SDOC should be supplied and endorsed by the authorised supplier of the equipment.

-

Should I install my own lights?

Should I install my own lights?

Unless it is a designated DIY product eg: floor lamp, or residential LED lamp, all SAL lighting products are designed for installation by a qualified electrical installer only.

-

Should I need to consider humidity and operating conditions?

Should I need to consider humidity and operating conditions?

Humidity can play havoc with electronic circuits (more commonly known in light as LED’s) This data can be found on SAL installation sheets and should be considered before installation of equipment.

-

Twitter - Does SAL have a Twitter feed?

Twitter - Does SAL have a Twitter feed?

Watch this space for updates of the release.

-

What does EMC stand for?

What does EMC stand for?

ElectroMagnetic Compatibility, which defines the use of different electronic devices (such as electrical appliances, medical equipment, LED’s and drivers etc) to operate without interference with other devices. This is a mandatory label (and testing) requirement for Australian and New Zealand Lighting equipment covered by AS/NZS CISPR 15. ACMA also recognise equivalent standards CISPR 15 and EN 55015.

-

What does IP stand for?

What does IP stand for?

IP (or Ingress and Protection) are an international standard reference which defines how well an electrical product seals itself against the intrusion of foreign bodies and moisture. The first digit I stands for intrusion of a solid object and the second digit P stands for the protection against moisture. In brief the higher the rating the more secure the product is against these elements.

As a guide IP20 is suitable for basic interior spaces eg: office areas, where IP55 and above would be suitable for exterior equipment such as floodlights.

For more information please refer to AS/NZS 60529.

-

What does L70 mean?

What does L70 mean?

For the digital LED world L70 is simply a measure of time that the light source will be reduced to 70% of its original (or initial) output. You will also see documented L90, which represents the measure of time where the product is reduced to 90% of its original (or initial output).

-

What does SAL corridorSTANDBY function mean?

What does SAL corridorSTANDBY function mean?

corridorSTANDBY what does it mean?

The SAL corridorSTANDBY function is a sensor designed for use in products such as bulkheads or weatherproofs for underground carparks and battens for commercial interior spaces to identify activity within the space, thus providing a set value of illumination for a determined amount of time.

In detail; the SAL corridorSTANDBY function allows the user to set the device to detect movement in the space, which then signals the product to switch to full brightness and then hold for a predetermined time, then when movement is NOT detected, the signal then reduces the lighting level to a predetermined value and allows function for a predetermined duration.

The SAL corridorSTANDBY function is ideal for commercial interior and underground carpark spaces, looking for an energy efficient lighting solution without compromising safety and security.

-

What is a LM79 report?

What is a LM79 report?

In street terms LM79 is a set of methodologies for laboratory testing of solid state luminaires, which will result in CCT, CRI, system power, luminous flux and distribution being reported.

-

What is a LM80 report?

What is a LM80 report?

In street terms LM80 is the test method for measuring lumen maintenance for a LED light source at the actual component level ie the LED.

-

What is a ta rating?

What is a ta rating?

(thermal ambient) is the recommended maximum environmental thermal limit for the safe continued operation of an electrical device. The ta rating can be found on the rating label and installation sheet, which is located on the relevant product web page. Typically, you will find ta ratings of 25 degree C for Interior products, where ta ratings of up to 50 degree C can be found for exterior products. Operating products beyond their designed ta limit is not recommended as it will stress the product components beyond their rated limits, resulting in reduced product performance or premature failure.

-

What is a TM21 report?

What is a TM21 report?

In street terms TM21 is a method to extrapolate the LM80 lumen maintenance data beyond the actual test duration and determine a projection of lumen maintenance as referenced by L70 or L90 (70% or 90% of the initial light source output).

-

What is an electrical CLASS I lighting product?

What is an electrical CLASS I lighting product?

This is a product that requires the installation of an earth to be compliant to AS/NZ 3000.

-

What is an electrical CLASS II lighting product?

What is an electrical CLASS II lighting product?

This is a product that does not require the installation of an earth to be compliant to AS/NZ 3000, as the product is a double insulation product.

-

What is an IK rating?

What is an IK rating?

An IK rating of a lighting product is covered by EN 62262 and is a measure of the impact resistance of a product. In brief the test process measures a products mechanical impact (impact energy joules) limits against a known mass and varied distances. As a guide the higher the IK rating (limit 10) the higher the products ability to withstand impact force.

High IK rated products (IK10) would be seen used in environments such as vandal prone installations, prisons as a guide.

-

What is Earth leakage current?

What is Earth leakage current?

Earth leakage current is an important electrical safety measurement and care should be considered when calculating earth leakage values. This data can be found on SAL installation sheets or for more details on the calculating method go to AS/NZ 60598.1.2013 table 10.3.

-

What is in-rush currents?

What is in-rush currents?

Like traditional HID circuits, LED despite the smaller electrical loads has its own limits when it comes to in-rush currents, which must be considered with all electrical circuits. This data can be found on SAL installation sheets.

-

What is SAL’s (NZ) customer service contact number?

What is SAL’s (NZ) customer service contact number?

HAMER NZ - 130 Bush Road Albany Auckland P# 0800 239 239

-

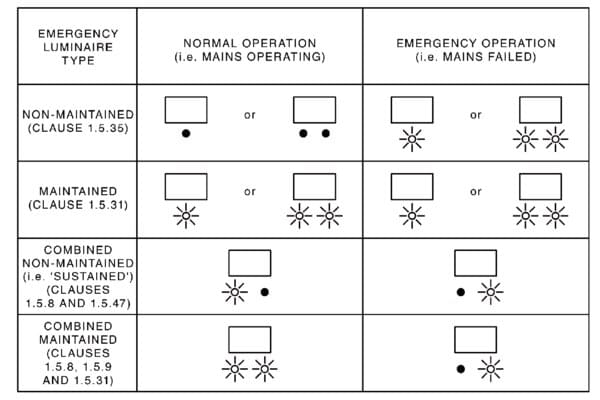

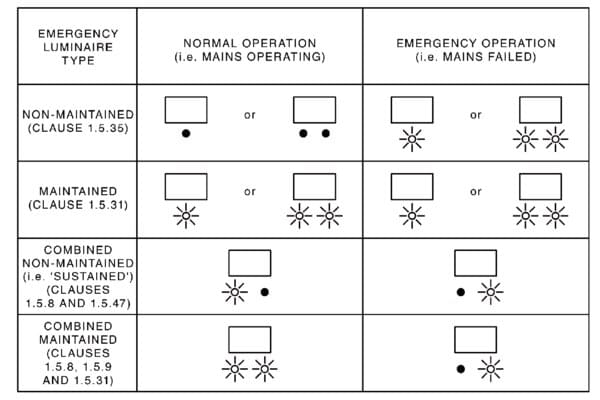

What is the definition of an Emergency maintained fitting?

What is the definition of an Emergency maintained fitting?

This is an emergency light that remains ON at all time and remains ON during a supply failure for the designated time as per AS 2293. Maintained lights are typically (but not limited to) EXIT signs.

-

What is the definition of an Emergency non-maintained fitting?

What is the definition of an Emergency non-maintained fitting?

A non-maintained emergency light is one that is only used (on) for emergency lighting, hence in the event of a mains (supply) failure, the emergency light source will be activated.

-

What is the definition of Colour rendering index?

What is the definition of Colour rendering index?

(CRI) in street talk is a measure of how an illuminated object appears to the eye. As a guide the higher the CRI rating >85, the closer the illuminated object is when compared to standardized daylight. Typical CRI value available are: CRI70 for outdoor recreational sports, CRI80 for interior task areas, >CRI90 clinical observation tasks.

-

What is the definition of Colour temperature?

What is the definition of Colour temperature?

Si (k) denotes the colour temperature of a light source referenced against a black body radiator.

In street terms colour temperature is how warm or cool you see the light source.

eg : warm colours are typically 2700-3000k, which would generally be used in residential interior spaces.

cool colours are typically around 4000k, which would generally be used in office interior spaces.

cold colours (daylight) are typically 5000-6000k, which would generally be used in exterior spaces. -

What is the definition of Lumen output?

What is the definition of Lumen output?

Lumen (lumen lm) is the total light out of a light source measured as (initial lumens) representing the base or NEW lamp source lumens. (Rated lumens) is then measured after 100 hours usage for traditional lamp sources and LED sources are represented by L70 or L90 ratings.

-

What is the definition of Lux?

What is the definition of Lux?

Lux (lx) is the unit measure for how much luminous flux (lumens lm), which in street terms is LIGHT falling on a given surface. Lux can be accurately measured by a calibrated Light meter

-

What is the standard warranty for SAL products?

What is the standard warranty for SAL products?

In line with SAL standard terms and conditions of sale the standard warranty is twelve (12) months, unless stated otherwise on the product installation sheet and web page.

-

What is the title of the lighting safety standard for luminaires?

What is the title of the lighting safety standard for luminaires?

The mandatory luminaire general requirements and testing is covered by AS/NZS 60598.1:2013. This standard addresses essential electrical and operating performance tests for a lighting product, which is a must when selecting lighting products.

This standard is in addition to specific product standards such as AS/NZS 60598.2.2-2016 and AS2293.1.2005 Emergency Lighting as an example. -

What should be found on the product rating label?

What should be found on the product rating label?

As a minimum you should find all necessary electrical data to allow you to be informed about the electrical characteristics of the product to enable a safe and compliant installation such as RCM mark, company logo, voltage, line current, power, frequency, power-factor, country of origin, IP rating, batch number ta rating, cover ratings if applicable.

-

Where can I buy SAL products?

Where can I buy SAL products?

SAL distribute their products through HAMER New Zealand Electrical. To find a store near you, simply input your postcode and available locations will be provided.

-

Where do I find the warranty term for SAL products?

Where do I find the warranty term for SAL products?

This information can be found on the product installation sheet located in the product carton or relevant product web page.

-

Where is SAL National’s HO?

Where is SAL National’s HO?

Villawood NSW 2163.

-

Who do I contact if I have special requirements that require an extended warranty?

Who do I contact if I have special requirements that require an extended warranty?

Simply follow the enquiry form on the WARRANTY page of this web site and a SAL team member will review the request and confirm the offer via a return email.

-

Why choose LED?

Why choose LED?

There many reason why to use an LED light source, however the two (2) headline reasons are;

(1) a significant reduction in electrical energy to achieve the same value of illumination and

(2) a significant reduction in operating costs. -

Will SELV products operate correctly when connected directly to a 12V DC battery source?

Will SELV products such as LED downlights, operate correctly when connected directly to a 12V DC battery source?

NO, as a member of Lighting Council Australia, SAL understands the importance of product compliance and such, maintain all products sold comply with all mandatory Australian, International safety, EMC and performance standards, which typically capture the use of lighting products connected to a traditional 240V / 415V 50Hz Electrical reticulation system.